Every year, several billion samples are examined in laboratories around the world as part of everyday clinical diagnosis and in the development of new medicines. These tests mostly involve the use of plastic pipette tips, which are used for manually or fully automatically dosing the fluids to be analysed – for the analysis of blood and PCR tests, for example – and are then conveyed to the analyser.

The production quality of these tips is crucial, as this is the only way to ensure that the correct dosage is applied and the samples are not contaminated. In order to reliably avoid false test results, pipette tips must undergo 100% inspection and satisfy stringent requirements for precision and quality without limitation.

This is where OCTUM comes in: With our pipette.inspect series, we offer you tailor-made inspection systems that guarantee seamless quality control of your pipette tips. Put your trust in our expertise and innovative technology, and be sure of maximum precision and cleanness. Contact us today and find out how pipette.inspect can improve your quality.

Any questions?

Get directly in touch with our

experts on +49 7062 91494-0

or write to us using our contact form

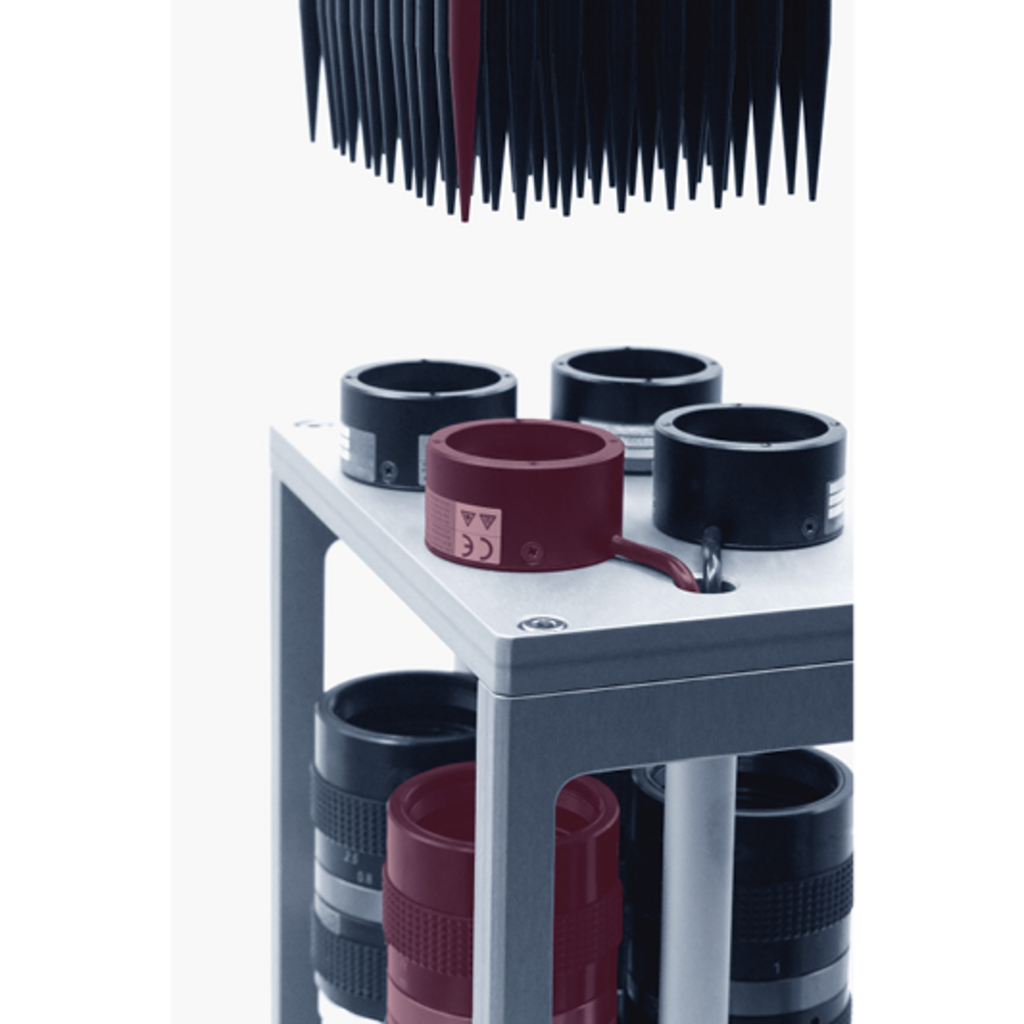

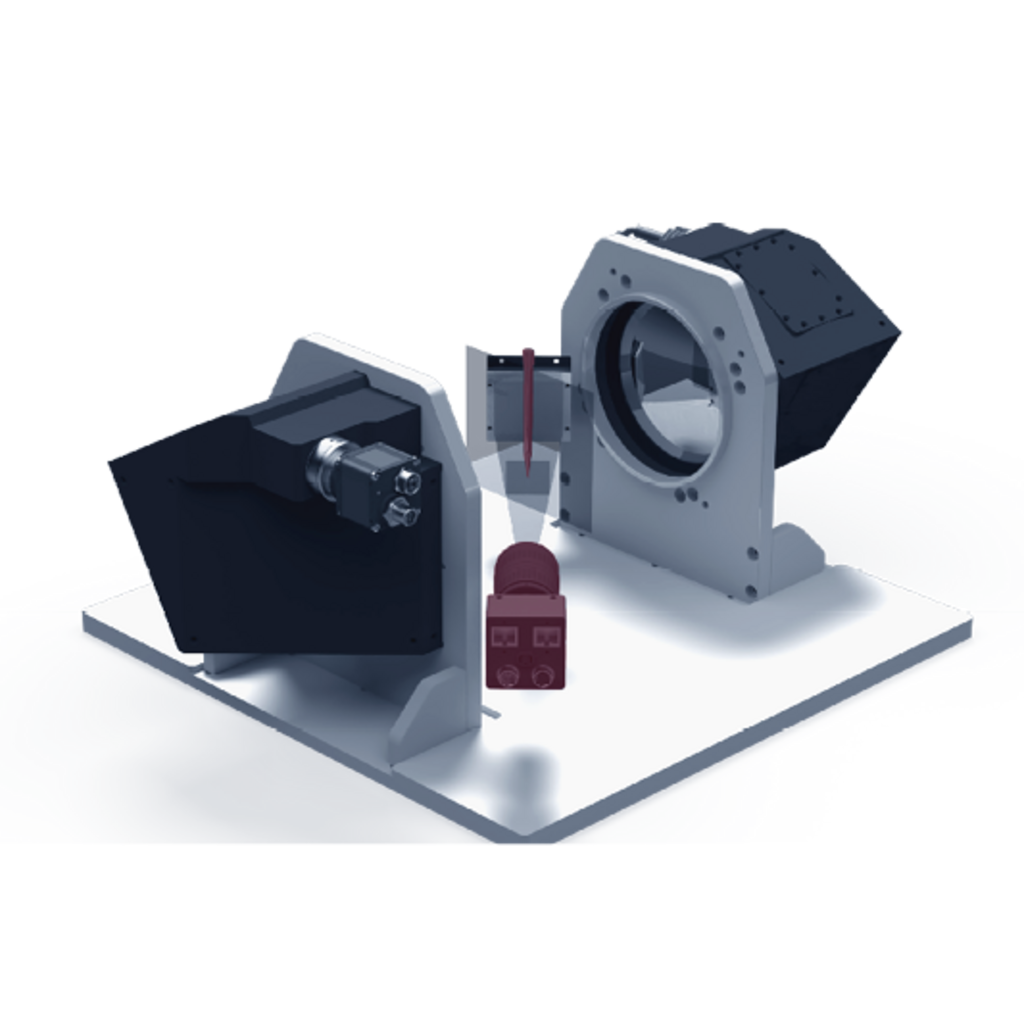

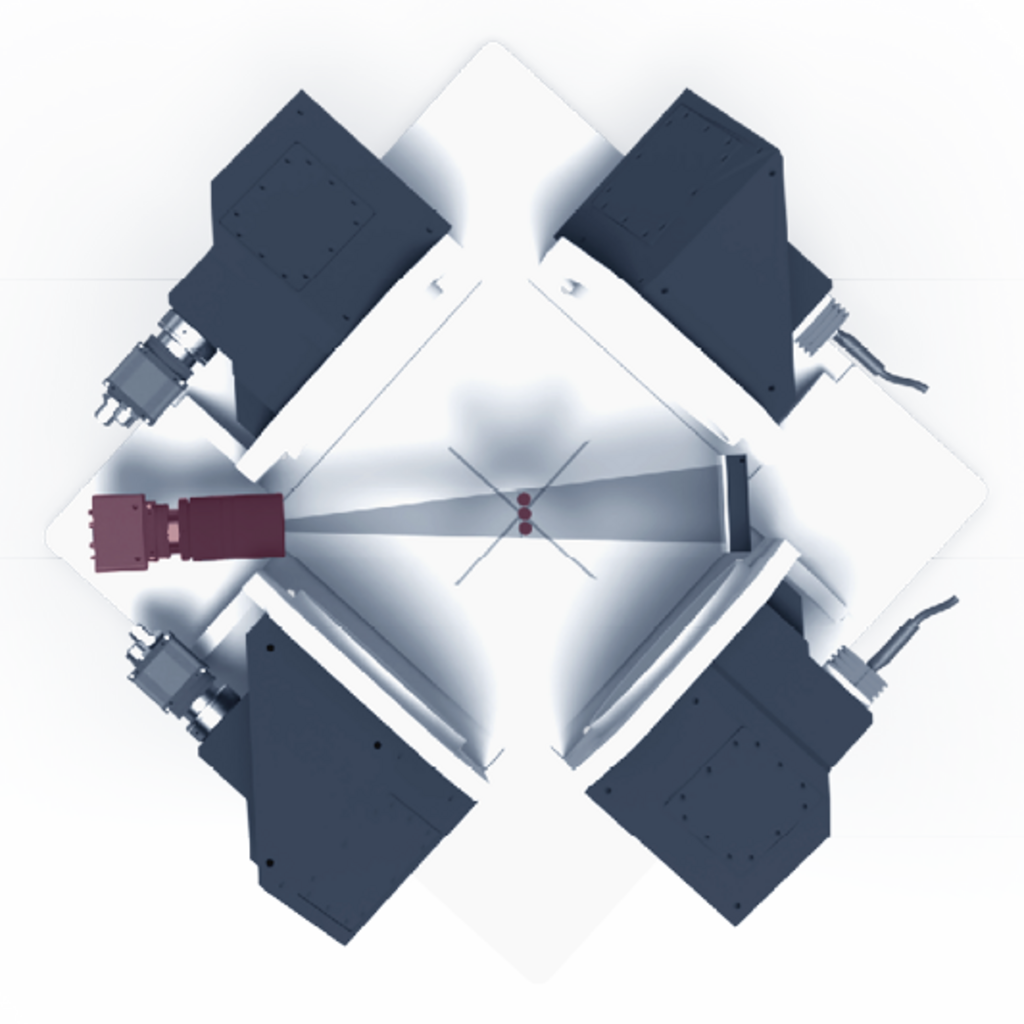

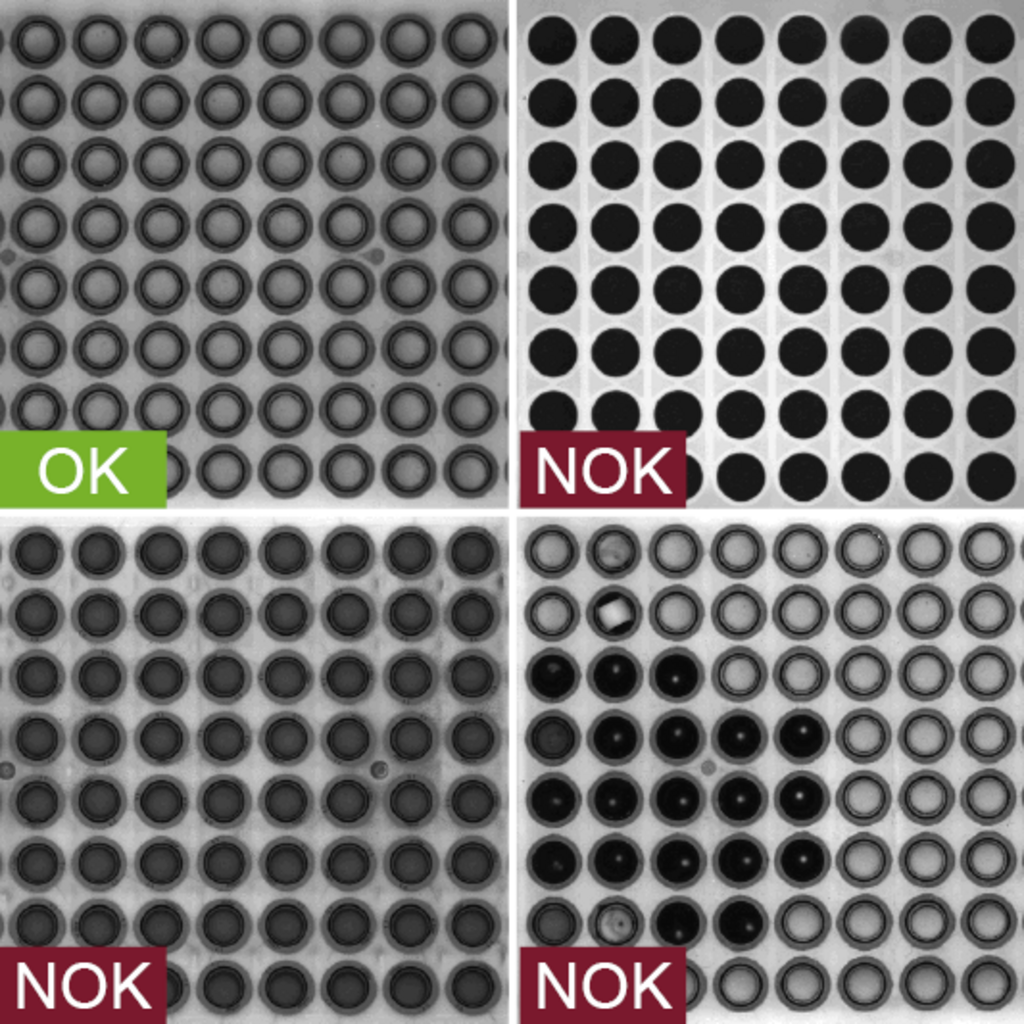

With inspection systems from OCTUM’s pipette.inspect series, manufacturers of pipette tips can enjoy peace of mind that end products will be defect-free. The automated systems analyse the geometry of each pipette tip from up to three perspectives, enabling reliable rejection of defective tips in accordance with standards EU GMP and 21 CFR Part 11. pipette.inspect systems from OCTUM have been successfully installed in the production lines of various pipette tip manufacturers for several years now. They enable reliable, high-precision tip inspection from all sides and are suitable for all common pipette sizes and materials. OCTUM has already successfully installed more than 35 systems from the pipette.inspect series.

- Inspection criteria:

- Inside and outside diameter

- Radial and axial flash

- Concentricity

- Short shots

- Filter presence

- Black and transparent tips

- New sizes can be set up quickly and flexibly

- Connection to business intelligence

- 21 CFR Part 11 and EU GMP compliant

- Machine cycle time: tray of 96/6.75 s

- User management and audit trails

- Proof of measuring equipment capability

- Other tip and tray sizes possible on request

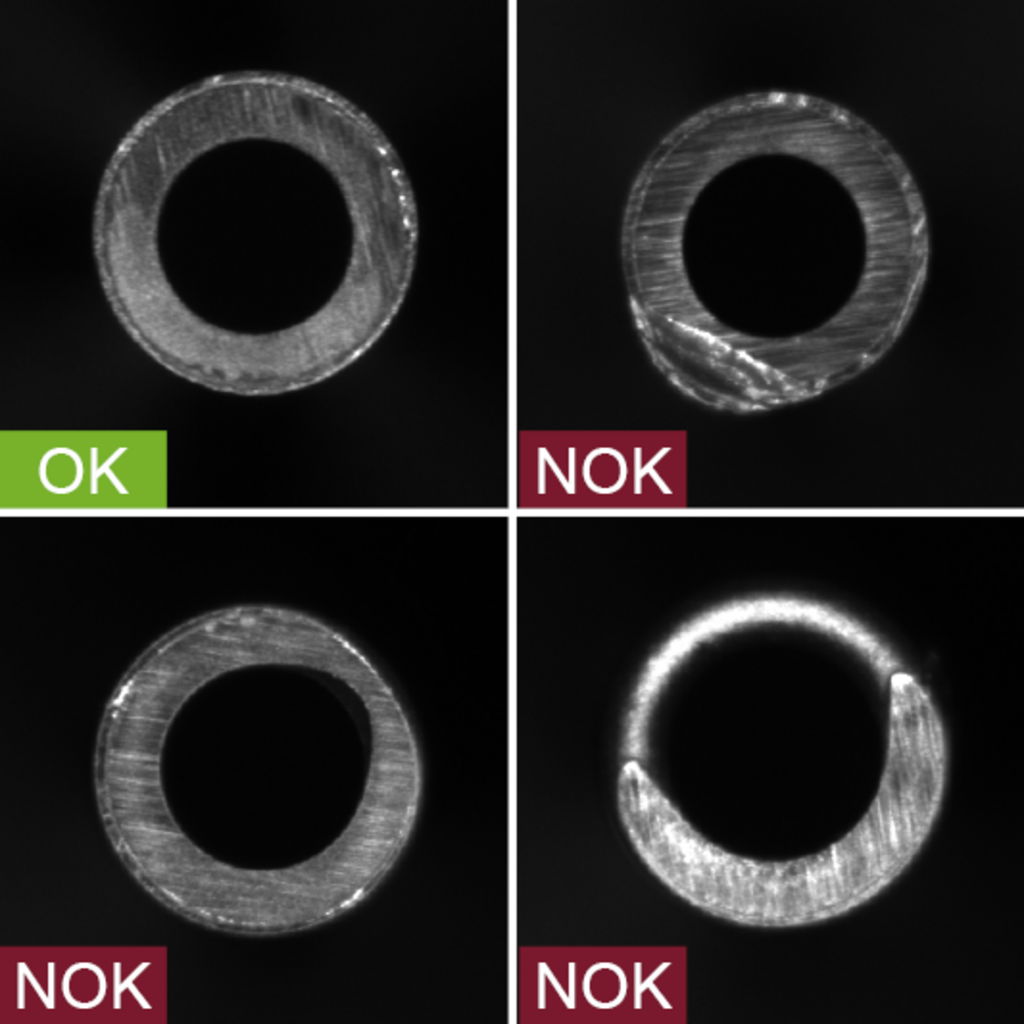

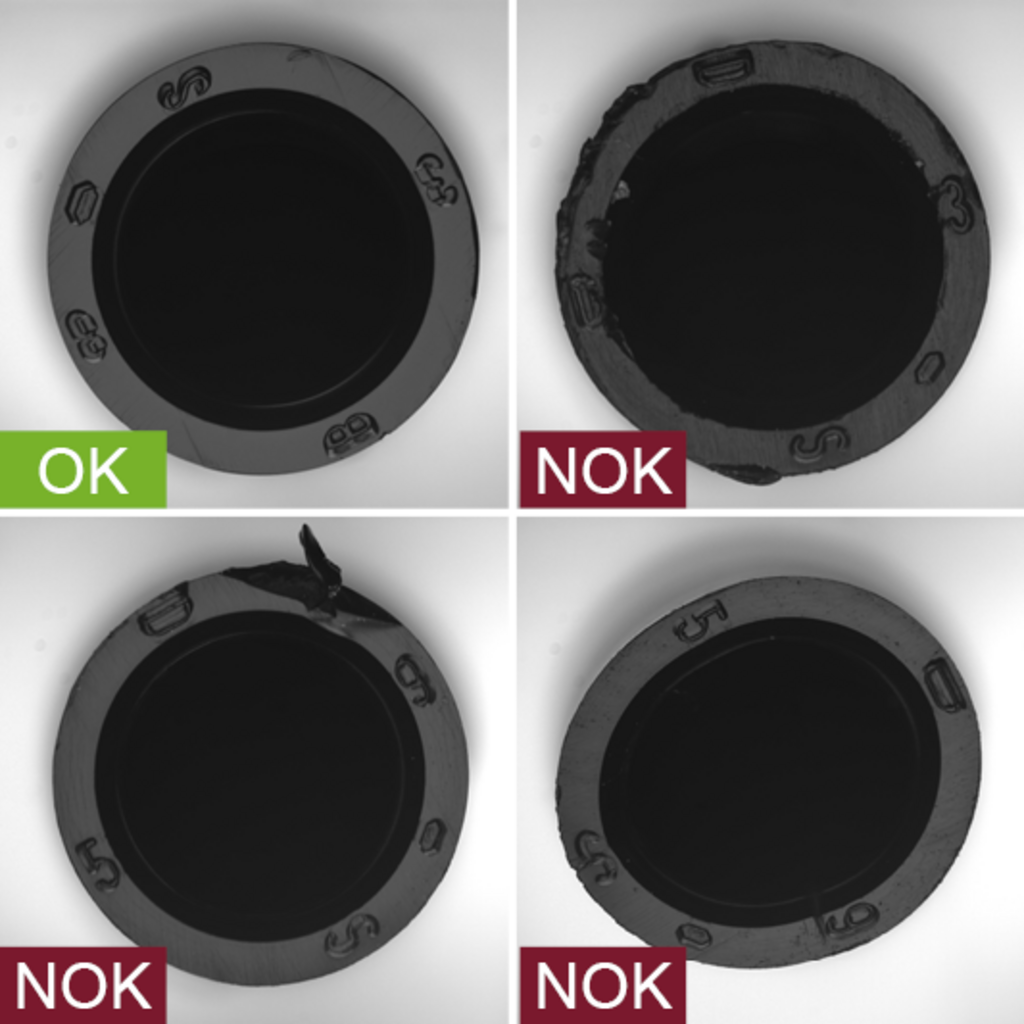

The Bottom View station checks the area around the pipette opening to ensure compliance with the specified inside and outside diameter. It also detects short shots or flash and checks that the integrated filter is present.

- Inspection zone:

- Pipette opening

- Inspection characteristics:

- Inside and outside diameter

- Short shots

- Radial flash

- Filter presence

- Defect sizes:

- from ± 0.025 mm (diameter)

- from 0.05 x 0.05 mm (flash)

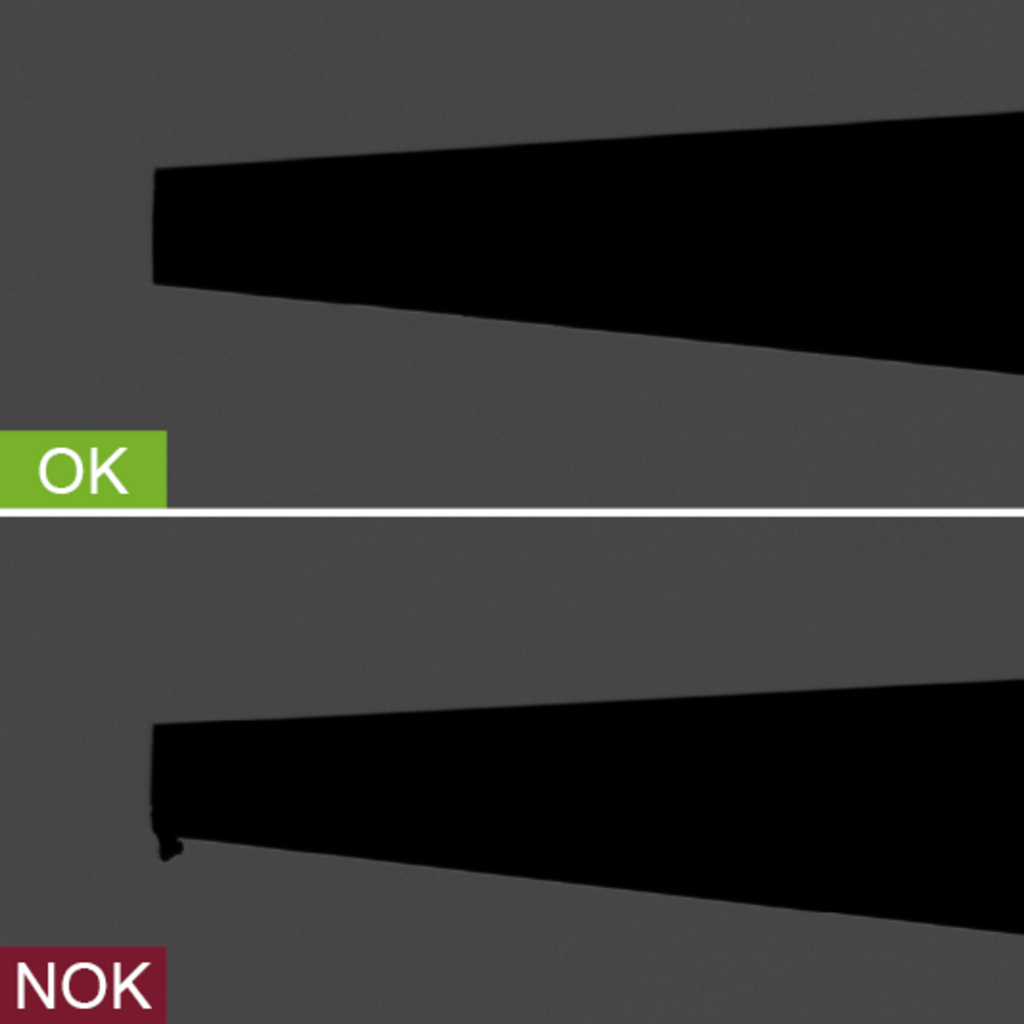

The Side View station inspects pipette tips for possible deviations from the specification. OCTUM helps you adapt to the specific pipette and tray sizes needed for your particular task.

- Inspection zone:

- Pipette tip

- Inspection characteristics:

- Concentricity

- Axial flash

- Defect sizes:

- from 0.5 mm (concentricity)

- from 0.05 x 0.05 mm (flash)

- Suitable for both 100% and random sample inspection

Top View

The job of the Top View station is to precisely examine the characteristics of the pipette collar. It analyses the inside and outside diameter and the roundness of this pipette section, detects short shots or flash and, as a supplementary check to the Bottom View station, also checks that the integrated filter is present.

- Inspection zone:

- Pipette collar

- Inspection characteristics:

- Inside and outside diameter

- Concentricity

- Excess and short fills

- Filter presence

- Defect sizes:

- from ± 0.05 mm (diameter)

- from ± 0.05 mm (concentricity)