OCTUM completes its product range for this sector with solutions for the automated inspection of medicinal syringes. syringe.inspect systems from OCTUM are designed for quality assurance in the production of glass and also plastic syringes with Luer lock adapter, Luer cone or safe dispensing tip, and are able to inspect up to 450 syringes a minute. They guarantee 100% quality in all three sub-processes of syringe production:

- Assembly

- Filling/sealing

- Packaging

Inspection systems from the syringe.inspect series are specially designed for the demanding requirements of the pharmaceuticals industry, such as 21 CFR Part 11 (USA) and EU GMP (EU), and enable the reliable detection and rejection of syringes and components that are not of the required quality. This way, defective components can be separated out at the earliest possible stage of the process, so that faults cannot propagate and the highest safety standards are complied with. Modular, expandable syringe.inspect systems therefore offer maximum safety in the production of top-quality syringes.

Any questions?

Get directly in touch with our

experts on +49 7062 91494-0

or write to us using our contact form

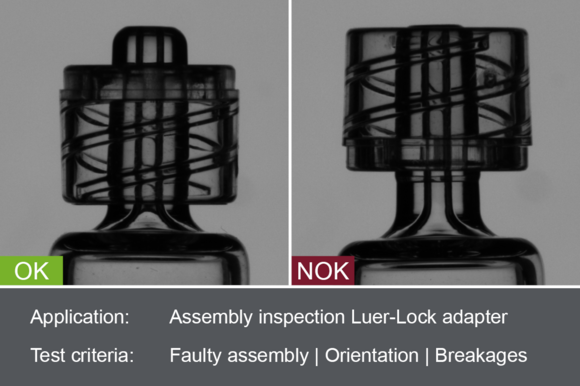

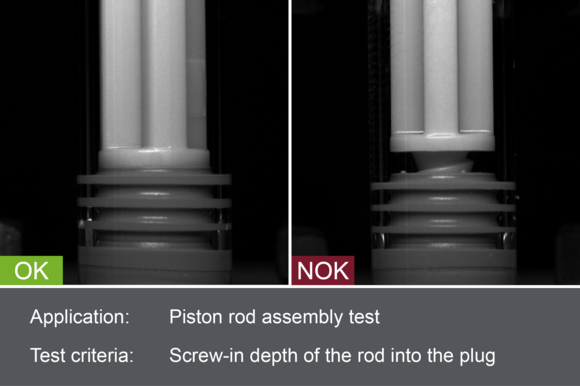

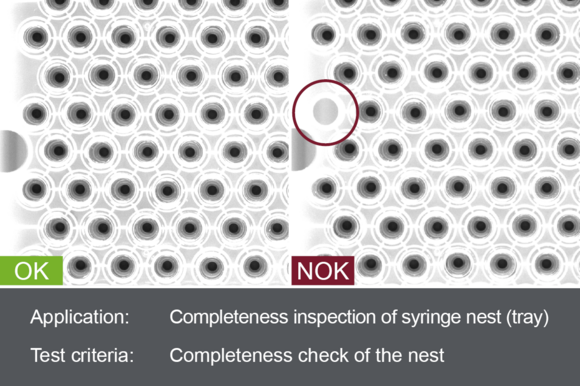

During the assembly process, syringe.inspect systems quickly and reliably detect defects and deviations from the specification, such as missing or incorrectly positioned dispensing tips, any kind of chipping on the Luer lock adapter or finger flange, incorrect total syringe length and uneven siliconisation of the inside of the syringe. This enables the reliable rejection of faulty parts before the syringes are filled.

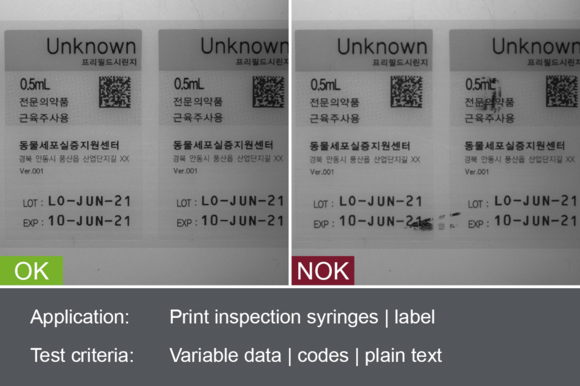

After the syringes have been assembled, they are filled with the medicinal product and the ready-to-use syringes are sealed. Even during this step, possible deviations from target parameters, different component states and the correct data and position of labels for syringe identification at high speed must be reliably detected. Here, too, syringe.inspect systems deliver 100% error-free results.

5 steps to your solution

It’s no small thing that quality assurance systems from OCTUM are also better because they are tailor-made for different requirements. For us, all-round support and advice – from analysis through engineering to implementation and service – are part of the package. With our syringe.inspect solutions, we ensure greater peace of mind in the production of syringes for medicinal use, all the way from assembly to the filling and sealing process.

![[Translate to Englisch:] eine rote Spritze wurde in ein Injektionsfläschchen gesteckt und wird aufgezogen](/fileadmin/user_upload/content-bilder/Branchenl%C3%B6sungen/Medizintechnik/syringe.inspect/Spritze_800x500_-_Kopfbild.jpg)