Wells and cups play a vital role in the development of active ingredients and diagnosis in ultra-modern laboratories, as they enable precise reactions in life science research. These reaction containers can be used for high-throughput screenings and diagnostic tests such as ELISA and PCR, for example. The production quality of the individual wells is crucial, as this is the only way to ensure that the samples are not falsified or contaminated by the containers themselves. Inspection solutions from OCTUM’s well.inspect series reliably prevent false test results and ensure that wells satisfy the exacting requirements for accuracy and quality without limitation.

Any questions?

Get directly in touch with our

experts on +49 7062 91494-0

or write to us using our contact form

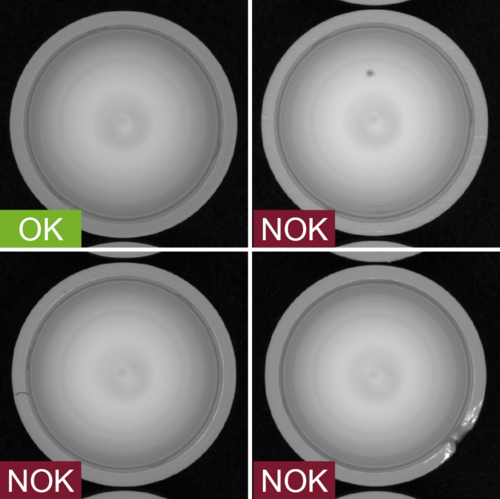

Inspection systems from OCTUM’s well.inspect series perform 100% fully automated geometry and surface analyses, enabling the reliable rejection of defective wells in accordance with standards EU GMP and 21 CFR Part 11. well.inspect systems from OCTUM have been successfully installed in the production lines of various manufacturers for several years now, and enable reliable, high-precision well inspection.

- Inspection criteria:

- Flaws

- Full shot

- Dark spots and stains

- Contamination

- Completeness in the tray

- Defect type classification

- New sizes can be set up quickly and flexibly

- Connection to business intelligence

- 21 CFR Part 11 and EU GMP compliant

- Modular system for easy expansion

- User management and audit trails

- Proof of measuring equipment capability

- Other well and tray sizes possible on request

![[Translate to Englisch:] auf einer Mikrotiterplatte ist ein Einzelwell rot markiert](/fileadmin/_processed_/e/e/csm_Well_800x500_-_Kopfbild_abeb949a65.jpg)