Toothpaste, medicinal products such as ointments, food, shoe polish, adhesives and many other types of merchandise from all areas of everyday life are available for sale in metal or plastic tubes. The diversity of these tubes is virtually incalculable. But there’s one thing they have in common: they must store their contents safely and precisely fulfil the specifications of their manufacturer in terms of size, tightness, appearance and many other properties and – in the case of tubes for medicinal products for example – meet exacting standards as well. The development of plants for producing these tubes requires a great deal of experience and sophisticated engineering. With tube.inspect, OCTUM is the perfect partner for making your tube inspection solution a reality!

Any questions?

Get directly in touch with our

experts on +49 7062 91494-0

or write to us using our contact form

- Used to inspect metal, laminate and plastic tubes

- For the 100% inspection of:

- Roundness

- Particles

- Trimming

- Codes

- Printed info on the base fold

- Tube diameters from 6 to 60 mm*

- Modular to enable expansion

- High machine speeds up to 500 tubes/min

- New sizes can be set up quickly and flexibly

- Central visualisation and control of all systems with one piece of software

- Flexible user management and audit trails

- 21 CFR Part 11 and EU GMP compliant

- With stainless steel enclosure on request

* Special sizes possible on request

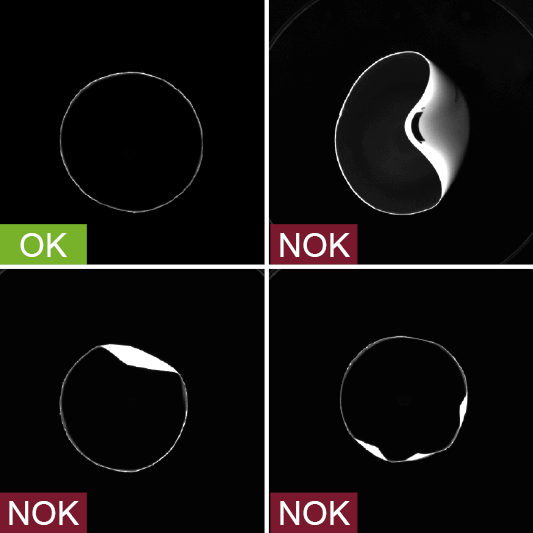

The roundness of the tube opening is a crucial feature before filling takes place. Openings that do not have the specified shape almost inevitably mean that material is sprayed into the filling system instead of into the tube during the filling process. This results in downtimes, a huge amount of time spent cleaning, and an uneconomical process. tube.inspect reliably prevents this problem by inspecting the roundness of tube openings before they are filled. The system recognises defective openings with certainty and rejects affected tubes before the filling process.

- Inspection zone: Tube opening

- Inspection characteristic: Open tube diameter

- Defect sizes*: approx. 2 x 2 mm

* Higher resolutions possible on request

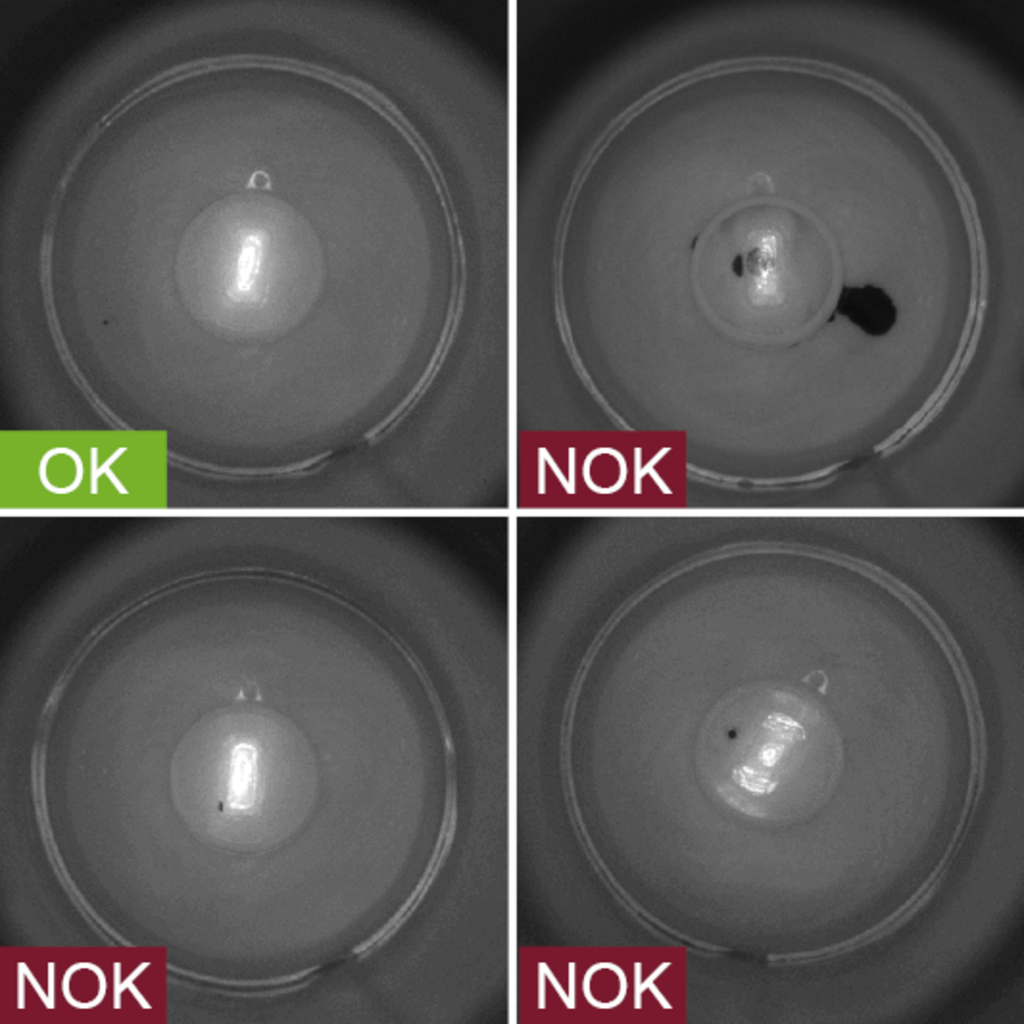

Soiled or contaminated empty tubes must be reliably detected before filling. This is particularly the case for tubes destined to contain food or medicinal products. tube.inspect enables reliable inspection of open tubes before they are filled. The system reliably detects tubes that are not clean and makes sure they are removed from the process.

- Inspection zone: Tube inside wall

- Inspection characteristic: Contamination

- Defect sizes*: approx. 0.5 x 0.5 mm

* Higher resolutions possible on request

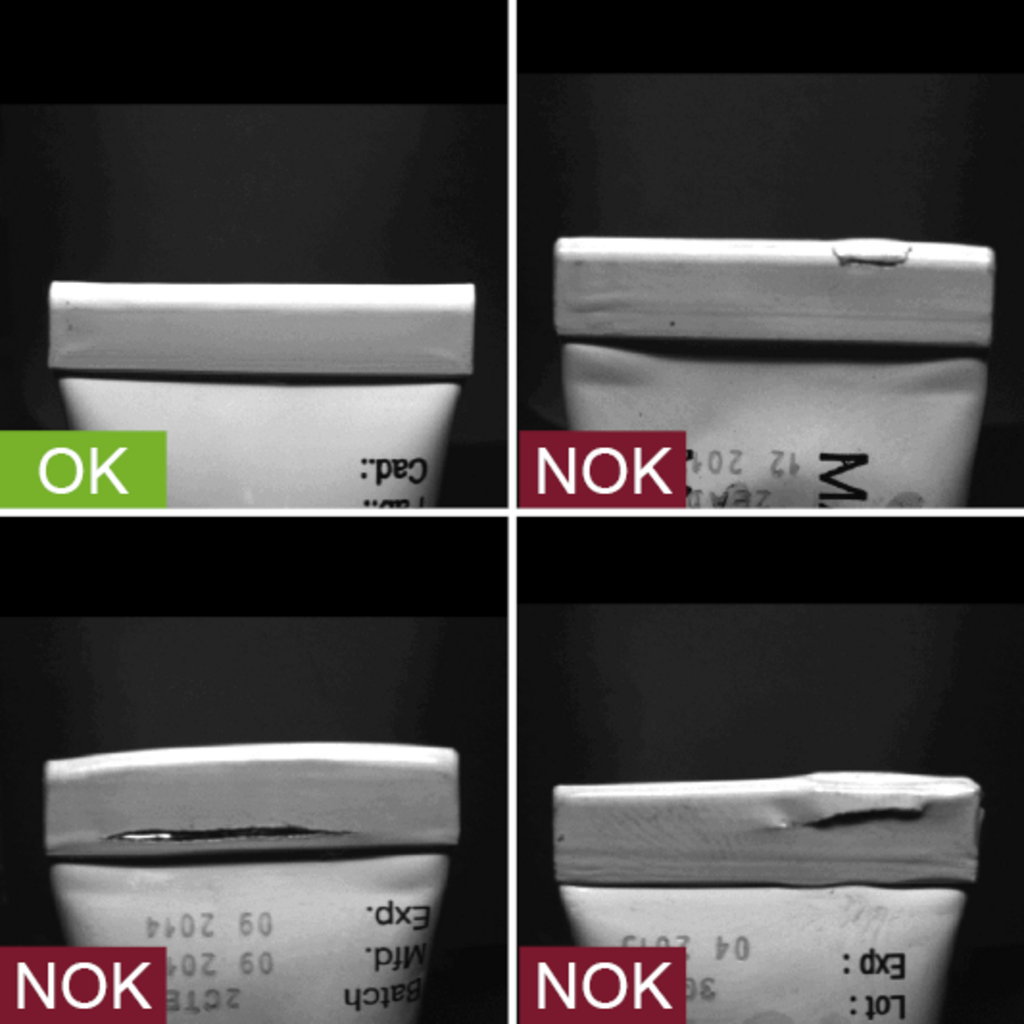

Only correctly filled tubes can be allowed to reach the market. Therefore, tube.inspect offers flexible options for reliably inspecting sealed tubes after filling for possible defects in the tube fold or seam, and for discarding non-compliant products. The system can be used for plastic, laminate and aluminium tubes, even though these containers may undergo different sealing processes.

- Inspection zone: Tube fold/tube seam

- Inspection characteristics:

- Correct sealing

- Protruding residues

- Trimming defects

- Location of seal marks

- Defect sizes*: from 2 mm

* Higher resolutions possible on request

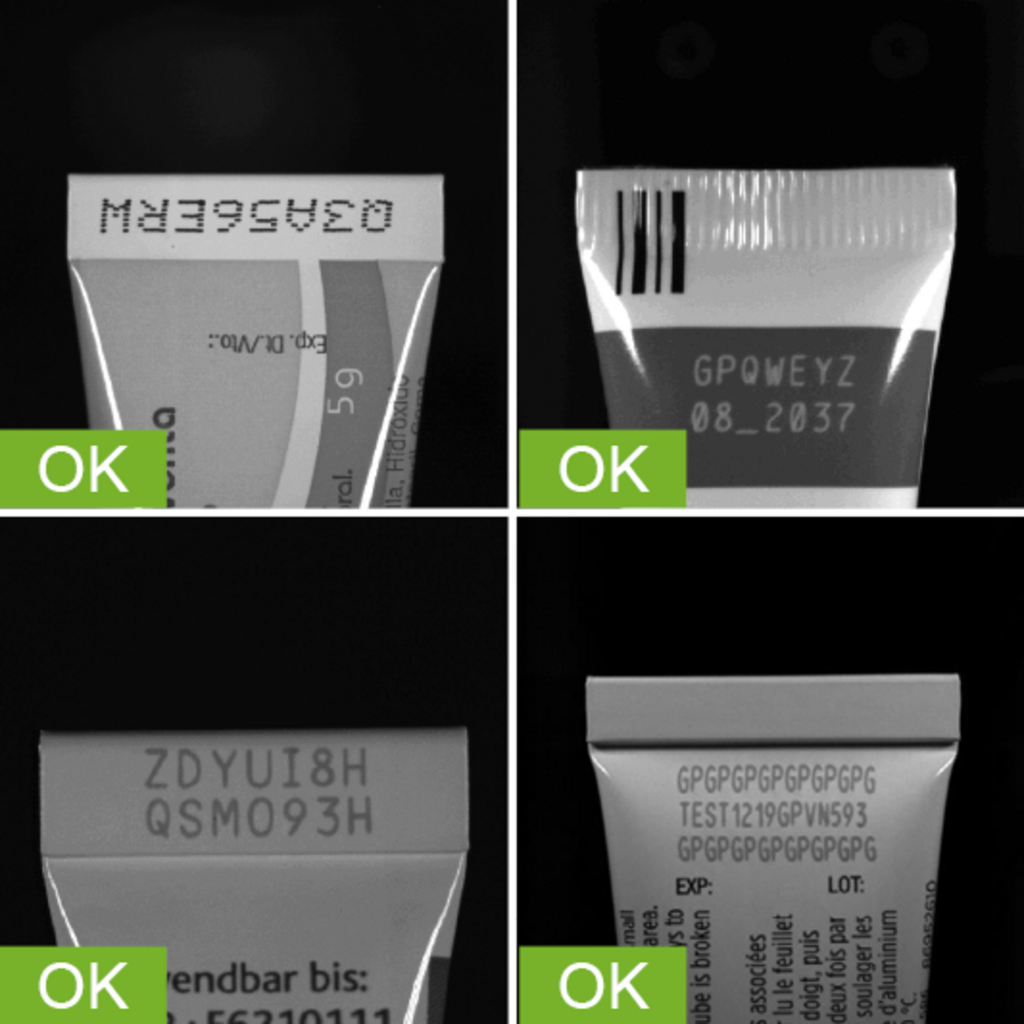

The design of tubes is an important recognition factor for customers and also frequently incorporates specifications that are stipulated by law. With tube.inspect, the print on sealed tubes can be examined after filling for a diverse range of aspects, in order to inspect or verify their markings, date of manufacture, expiry date and also the correct appearance of the tube. In this way, incorrect and illegible print can be reliably detected and defective tubes are sure to be rejected.

- Inspection zone: Tube marking

- Inspection characteristics:

- Printed text verification

- Data verification of batch numbers, serial numbers, date of manufacture, expiry date, etc.

- Verification of all common 1D and 2D codes (barcodes, data matrix, etc.)

- Print quality inspection

- Comparison with specified values

- Printing methods:

- Laser

- Inkjet

- Suitable for all tube sizes and colours

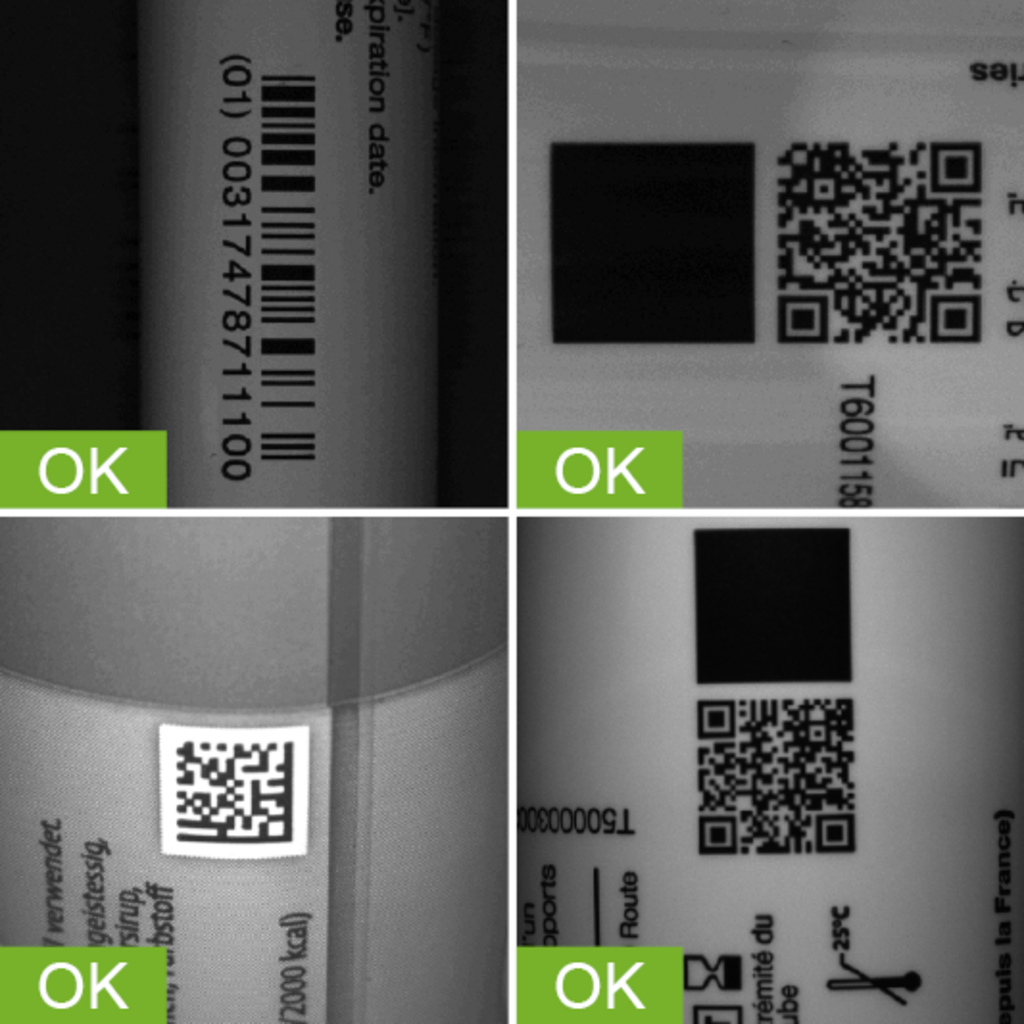

In many cases, 1D or 2D codes are applied to filled, sealed tubes, which enable the clear identification of data such as the content and date of manufacture. To ensure the reliable inspection or verification of these codes, tube.inspect offers all the necessary options and therefore makes absolutely sure that tubes with faulty codes are detected and rejected.

- Inspection zone: Tube marking

- Inspection characteristics:

- Verification of all common 1D and 2D codes (barcodes, data matrix, QR, etc.)

- Print quality inspection

- Comparison with specified values

- Printing methods:

- Laser

- Inkjet

- Suitable for all tube sizes and colours

![[Translate to Englisch:] in einer Füllmaschine für Tuben werden auf einem Rundtisch mehrere Tuben nach dem Verschließen verarbeitet](/fileadmin/user_upload/content-bilder/Branchenl%C3%B6sungen/Verpackungstechnik/Tuben__800x500_-_Kopfbild-gr%C3%BCn.jpg)