Ampoules are little glass bottles that are frequently used in medicine for storing liquids such as medicines and vaccines in sterile conditions. Inspection of these ampoules is indispensable in order to guarantee product quality and safety.

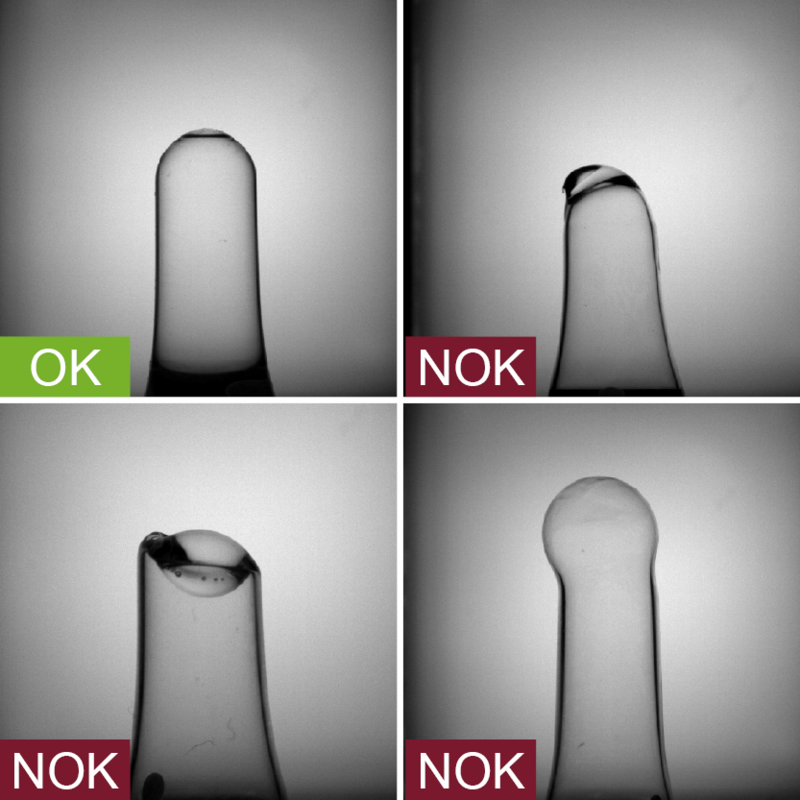

Our ultra-modern ampoule inspection systems from the ampoule.inspect series can precisely detect flaws such as air pockets, sunken areas, burn marks and unsealed, pointed or broken ampoules. Size adjustments can be made efficiently with the inspection program and the height-adjustable camera and light, enabling flexible inspection of ISO ampoules. Our systems are the perfect solution for filling and sealing machines, because they inspect the ampoules immediately after sealing and cooling, preventing the risk of injury from faulty ampoules.

Discover our tailor-made inspection solutions for the pharmaceuticals industry – Contact us!

Any questions?

Get directly in touch with our

experts on +49 7062 91494-0

or write to us using our contact form